| Product Line | Product | Position | Metallurgy | Vane Design | Coating |

|---|---|---|---|---|---|

| Optimum | SAE G10H18 (standard iron) through High Carbon |

Matches OE | Grey Fusion 4.0® | ||

| Midgrade | SAE G10H18 (standard iron) through High Carbon |

Matches OE | Painted Hat & Edges | ||

| Entry-Level | SAE G10H18 (standard iron) through High Carbon |

Matches OE | Bare Bare (Rust Preventative Oil for Shelf Life) |

||

| Performance | Enhanced Iron | Matches OE | Black Fusion and Grey Fusion 4.0® | ||

| Specialty - Police | Enhanced Iron | Reinforced OE | Grey Fusion 4.0® | ||

| Specialty Truck & Medium Duty | Enhanced Iron | Matches OE | Grey Fusion 4.0® | ||

| Entry-Level | SAE G10H18 (standard iron) through High Carbon |

Matches OE | Bare (Rust Preventative Oil for Shelf Life) |

Rotor Metallurgy: Rotors are made from several iron grades. Those iron grades are selected by the strength and durability requirements of that application. Most rotors (OE and aftermarket) fall under the SAE G10H18 (G3000) classification, high-carbon and alloyed variations make up the remaining varieties.

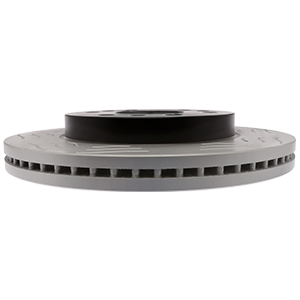

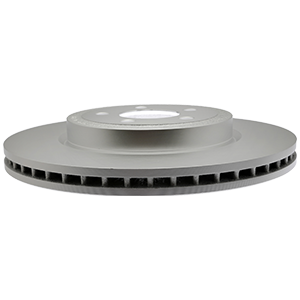

Rotor Vanes: Rotor vanes are designed to properly transfer the intense heat generated by the brake system to the passing air. By following vane structures as the OE intended, it ensures that the rotor dampens noise generating vibrations and resists thermal fatigue over the life of the rotor. Short-cutting design or reducing mass will lead to a shorter rotor life.

Rotor Coatings: Coatings provide corrosion protection and extended rotor life compared to uncoated or bare rotors. The paint used on the R-Line+ is a resin-modified material that is chemically resilient to withstand 120 hours in salt chamber testing. The Grey Fusion 4.0® provides optimal corrosion resistance for the entire rotor and faster brake jobs.